CALL 800-985-6929

Mon-Fri 7AM - 7PM CST

Delta VFD007C23A VFD-C2000 Series Drive

- Series VFD-C2000

- 0.75 kW

- 1 HP

- 5 Amps

- 230 V

- 3 Phase

The VFD-C2000 series is a high performance FOC (Field Oriented Control) AC drive. This drive is extremely versatile with a real built-in PLC, numerous control options, over 300 parameters, predesigned application features, and a large LCD HMI keypad. These features coupled with input voltages of 230/460vac and a HP range of 1-800 make the C2000 a product for markets around the globe.

Delta VFD007C23A

Delta Products

AC Drives, C2000 Series

ITEM # VFD007C23A

MFG # VFD007C23A

Series C2000

Drive, AC, 1HP, 230V, 3PH, 5A

Specifications

Item Number: VFD007C23A

Manufacturer: Delta Products

Item Category: Drives

Subcategory: AC

Series: C2000

Nominal Input VAC: 230 Volts AC

Input Range VAC: 170 to 265 Volts AC

Amps (CT): 4.8 Amps

HP (VT): 1 Horsepower

Amps (VT): 5 Amps

Input Phase: 3

Operator Controls: Keypad Included

Braking Type: DC Injection;Dynamic Braking;AC Line Regenerative

Motor Control-Max Level: Closed Loop Vector

Closed Loop: Yes

AC Line Regenerative?: Yes

Dynamic Braking Trans?: Included

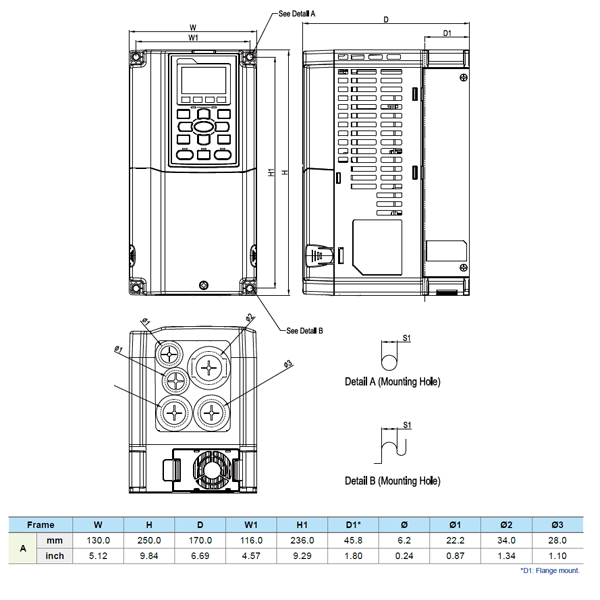

Frame Size: A

Height: 9.84 Inches

Width: 5.12 Inches

Depth: 6.69 Inches

Delta VFD C-2000 AC Drive Accessories

| Item # | |

| Delta CMC-EIP01 | Ethernet/IP and MODBUS TCP Card |

| Delta CMC-MOD01 | Modbus TCP Communication Card |

| Delta CMC-DN01 | Ethernet/IP and MODBUS TCP Card |

| Delta CMC-PD01 | Profibus Communication Module |

| Delta EMC-BPS01 | EMC-BPS01 24VDC External Power Supply Card |

| Delta EMC-COP01 | EMC-COP01 CANopen Card |

| Delta EMC-D42A | EMC-D42A I/O Extension Card 4I/2O |

| Delta EMC-D611A | EMC-D611A I/O CARD 110VAC 6 Input |

| Delta EMC-PG01L | EMC-PG01L Encoder Feedback Card |

| Delta EMC-PG01O | EMC-PG01O Encoder Feedback Card |

| Delta EMC-PG01R | EMC-PG01R Resolver Feedback Card |

| Delta EMC-PG01U | EMC-PG01U Encoder Feedback Card |

| Delta EMC-R6AA | EMC-R6AA Relay Extension Card 6 Form A |

| Delta MKC-D0N1CB | MKC-D0N1CB Conduit Box Kit Frame D NEMA1 |

| Delta KPC-CE01 | KPC-CE01 LED English Keypad |

| Delta KPC-CC01 | KPC-CC01 Single Line LCD Keypad |

| Delta BR200W091 | Braking Resistor |

| Delta BR200W360 | Braking Resistor |

| Delta BR300W070 | Braking Resistor |

| Delta BR300W250 | Braking Resistor |

| Delta BR400W040 | Braking Resistor |

| Delta BR400W150 | Braking Resistor |

| Delta BR1K0W016 | Braking Resistor |

| Delta BR1K0W020 | Braking Resistor |

| Delta BR1K0W4P3 | Braking Resistor |

| Delta BR1K0W5P1 | Braking Resistor |

| Delta BR1K0W075 | Braking Resistor |

| Delta BR1K2W015 | Braking Resistor |

| Delta BR1K2W3P9 | Braking Resistor |

| Delta BR1K5W012 | Braking Resistor |

| Delta BR1K5W013 | Braking Resistor |

| Delta BR1K5W043 | Braking Resistor |

| Delta BR1K5W3P3 | Braking Resistor |

Manuals and Specifications

| Catalog | Delta VFD-C2000 Series Catalog | |

| Users Manual | Delta VFD-C2000 Users Manual | |

| VFD Panel Packages | Delta VFD-C2000 Drive Panel Packages |

Delta Bypass Panels play an important role in a system to reduce energy usage,optimize AC motor speed control, extend motor life, and reduce overall cost. The bypass capabilities allow the motor to be operated from either the Delta VFD or at full speed, directly across the line. The Delta Bypass Panel sets a benchmark for cost, performance, quality, and custom engineered bypass panels. Delta offers both the standard bypass panel, or our custom engineered panel to fulfill all your specification requirements.