CALL 800-985-6929

Mon-Fri 7AM - 7PM CST

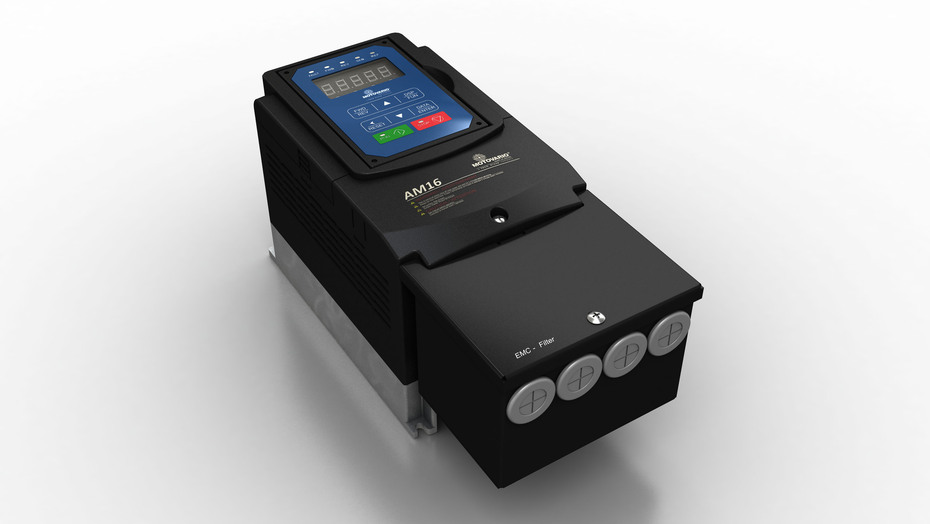

AM16 REPRESENTS: SUPER TECHNOLOGY – SUPER EXCELLENCE – SUPER EVOLUTION

The super evolution of AM16 made it debut which combined customer responses with Innovation.

Advanced current vector control inverter – AM16. Except the Auto-tuning and support for the PM motor, the core computing of AM16 raises to 60%. The all new technologies make our inverters better. Please feel the charming of AM16.

7 TYPES OF MOTOR CONTROLS

AM16 can support many industries such as elevator, crane and compressor.

AUTO-TUNING SUPPORT

Advanced Rotational – Static and Stator resistance Auto-tuning modes.

WIDE RANGE OF APPLICATIONS

Easily transfer to specific parameters for dedicated application. 16 V/F curves for wide range of applications.

HIGH LEVEL SENSOR VECTOR MODE

Support to induction motor and permanent magnet motor. AM16 promotes motors to optimum condition.

MUCH FASTER FOR COMPUTING ABILITY

Dual core processors. Faster computing ability, Larger ROM and RAM.

CONFORMITY TO GLOBAL STANDARDS

RoHS – CE – UL. Provide safety function such as fire mode.

DUAL CORE PROCESSOR

ENHANCED PERFORMANCE & RELIABILITY

- ASIC

Prevents inrush current damage to IGBT module. Enhances the reliability and life expectancy of motor drive.

- 32BIT MCU

Mass computing capability for advanced current vector control technology. Minimizes the internal loop time for higher control response.

MORE POWERFUL IN CORE COMPUTING

New core processors and better computing ability

| CORE COMPUTING | ROM | RAM |

| RAISE 60% | RAISE 100% | RAISE 530% |

ADVANCED MOTOR

AUTO-TUNE FUNCTION

Multiple Auto-tune Modes

| Rotational auto-tune mode | Rotary-type auto-tune for higher performance for precise control |

| Static auto-tune mode | The motor shaft will be locked in static auto-tune mode |

| Stator resistance measurement | Auto measure the resistor within cable and compensate accordingly |

5TH KERNEL

AM16 is loaded with 5th generation kernel has the most advanced motor tuning function to build accurate motor equivalent model automatically.

Optimized current vector control performance provides faster commissioning.

200% – 0,5H z STARTING TORQUE CONFORMITY TO GLOBAL STANDARDS

SensorLess Vector (SLV) control mode achieves incredible 200% torque performance at extreme low speed 0,5Hz. Provides stable control experience for wide range of applications.

CONFORMITY TO GLOBAL STANDARDS

Conformity to RoHS directive and international recognized certification.

HIGH EFFICIENCY PM MOTOR DRIVING

Simple parameter settings for easy switching between induction and permanent magnet motors.

High performance current vector control for induction and permanent magnet motors.

FAN CONTROL AND QUICK RELEASE

Lower noise and extend the life of fan.

Quick replaceable fan make customers be easy to change it.

ULTRA LOW MOTOR NOISE

Traditional PWM modulation method

Unique Soft PWM modulation technology lowers the audible motor noise for quieter industrial environment.

INTELLIGENT OVER VOLTAGE SUPPRESSION

Suppress over voltage caused by regenerative loads and redirect regenerative energy back to the load. Intelligent overvoltage suppression will not only protect the drive but also no need for costly braking units.